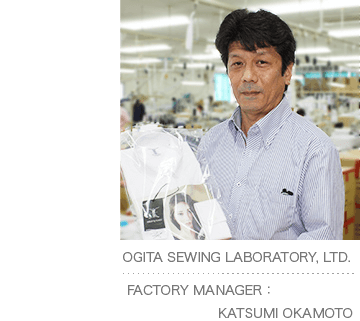

Our company started up as a domestic factory of OGITA HEMD, LTD. in 2011. At first, we made samples and products in small quantities with 10 employees, but we didn't have much skills to make dress shirts.

From the second year on, we expanded our productive capacity by bringing in new equipments and arranging our production floor. Now we have 30 employees, improving our skills day by day.Besides dress shirts, we make casual shirts, ladies blouses, and other shirts that has a special design.

It is our aim to present the sureness of Japanese product's quality.

- Name of the company: MITOYO SEWING, LTD.

-

Address:

3043 Toyonakacho Kasadakasaoka,

Mitoyo-shi, Kagawa-ken 769-1502, Japan

TEL : +81-875-62-5401

FAX : +81-875-62-6085 - Established: January 2011

- Number of employees: Production 36 / Inspection 2

- Monthly Production 2,700 to 3,000

We make both casual OEM products and our own products.

Cutting, sewing, and finishing is all done in a same floor. As a part of upskilling, we are bringing in new machines such as buttonholding indexer for placket, and semi-automatic button sewing machine. When making a dress shirt, we take care to sew carefully to raise the quality, and when making a casual shirt, we do our best to meet customer's requests.

①Planning

②Making processing instructions and sewing specifications

③Pattern making

④Arranging materials

⑤Checking the materials and the documents

⑥Cutting

⑦Sewing

⑧Finishing (ironing, holding, inspecting)

⑨Shipping

-

Cutting facilities:

Rolling machine /1

Hand knife /2

Cutting machine /3 -

Sewing facilities:

Final sewing machine /22

Final sewing top and bottom forwarding /3

Final sewing needle forwarding /2

Interlock sewing machine /2

Overlock sewing machine /1

Arm double hooking sewing machine /1

Fly double hooking sewing machine /1

Interlock stitch machine /1

Double ring sewing sewing machine /1

Scoop sewing machine /1

Neckband cuff cosmetic surgery press /2

Buttonholding Indexer /1

Buttonhole stitch machine /3

Sewing machine with button /3

Perception stopper sewing machine /2 -

Finishing equipment:

Vacuum iron /9

Finish neck press /1 -

Pattern:

Apparel CAD /1

Plotter /1

Flat model plotter /1

Actual size marker /1